Urban Landscapes are Changing

by Welcome 716

The real estate sector in Australia keeps growing at a phenomenal rate. According to available data, the residential property market has touched the magical figure of $11 trillion. The yearly hike was pegged at $900 billion. As urban real estate and infrastructure development pick up pace, realtors and construction firms are opting for sustainable, robust, and efficient solutions. In major Australian cities and developing regions, fabricated steel is increasingly used for construction increasingly used for construction.

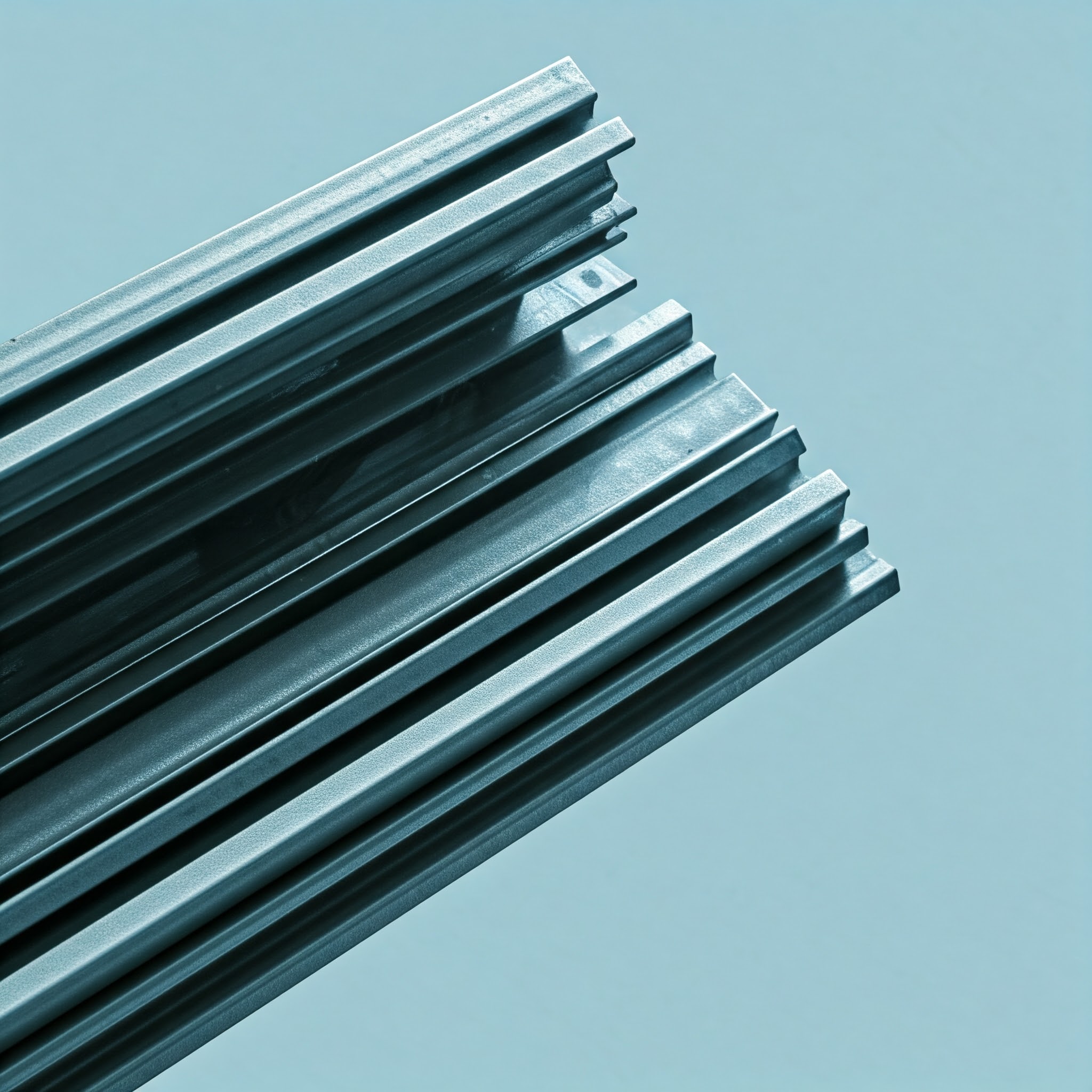

The role of steel fabrication as the cornerstone of urban construction

Steel fabrication involves specific procedures for cutting, moulding, and assembling steel components for excellence in construction. Its sheer flexibility and precision make fabricated steel a preferred component for various urban construction projects.

- High-rise building construction requires lightweight but robust components, and fabricated steel fits the bill nicely.

- Steel fabrication is used to make bridges and flyovers in urban regions.

- Steel fabrication is used.

- in various urban commercial construction projects, including shopping malls and entertainment hubs.

The core benefits of using steel fabrication for urban construction projects

There are multiple reasons for choosing fabricated steel for different urban construction needs:

- Excellent durability and ruggedness – Urban buildings need a structure with unmatched strength, and that is what fabricated steel offers. In coastal cities, buildings cope with harsh weather conditions, including extreme heat, rain, and wind. Buildings with structures made of fabricated steel parts have coped with such weather issues for years.

- Good sustainability – With time, more real estate firms in Australia are switching to sustainable development practices. Steel fabrication easily meets such entities’ sustainability goals. Steel can be recycled, reducing the environmental impact significantly.

- Faster completion – In many urban construction projects in Australia, completing the projects within the deadline is important. With Prefabricated steel components, construction companies can easily adhere to deadlines, and fabricated steel is also easy to transport.

- Flexibility in design – Several urban buildings and commercial establishments are designed with high aesthetics. To implement such designs into reality, fabricated steel is useful. This material can be moulded into varying geometric shapes easily. Several popular Australian landmarks have been developed using this component.

- Low maintenance cost – Structures and buildings developed using fabricated steel components last longer and require less maintenance.

- Safety norms – Modern urban buildings must adhere to the latest safety norms to survive natural calamities. Construction should be done with rugged components in cities located near seismic fault lines. Fabricated steel structures can cope well with shocks and flex. They are ideal for use in earthquake-prone regions.

Choosing the right supplier for fabricated steel

Construction sector entities should procure fabricated steel components from reliable and veteran manufacturers. To start with, they should check the product range of such brands. Metro Steel, for example, offers a huge range of high-quality fabricated steel parts and accessories. Besides, factors like their certifications and deployment of the latest manufacturing technologies should be checked. Top-notch steel fabrication companies offer detailed consultations for various clients.

0 Comments